Bureau d’études mécanique

Maîtrise & savoir-faire

Notre expertise et méthodologie

Un accompagnement sur mesure

Une expertise technique éprouvée

Conception mécanique

(CAO 2D/3D, calculs, dimensionnements)

Gestion de projets

(planning, qualité, coûts)

Nous intervenons sur des projets à forte valeur ajoutée technique, dans des environnements exigeants.

Une méthodologie projet claire

Conception & intégration

Nos services d’ingénierie

Le bureau d’études AMCC, accompagne ses clients industriels dans leurs projets mécaniques clés en main, de la conception jusqu’à l’intégration finale. Notre savoir-faire s’articule autour de trois domaines complémentaires :

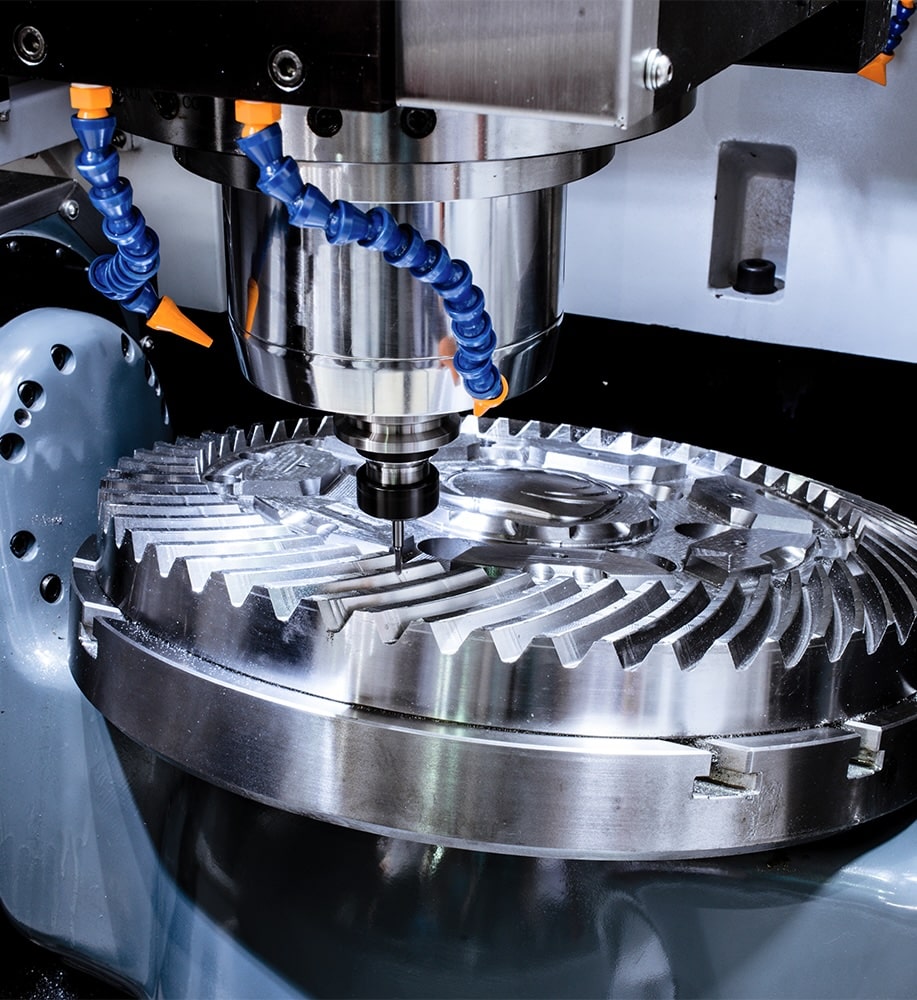

Conception mécanique

AMCC accompagne ses clients dans la conception de projet mécanique et le développement de solutions innovantes.

EN SAVOIR PLUSFabrication

Notre expérience et notre réseau de partenaires nous permettent de vous épauler dans vos projets de fabrication de la micro pièce très précise à des ensembles de tailles conséquentes.

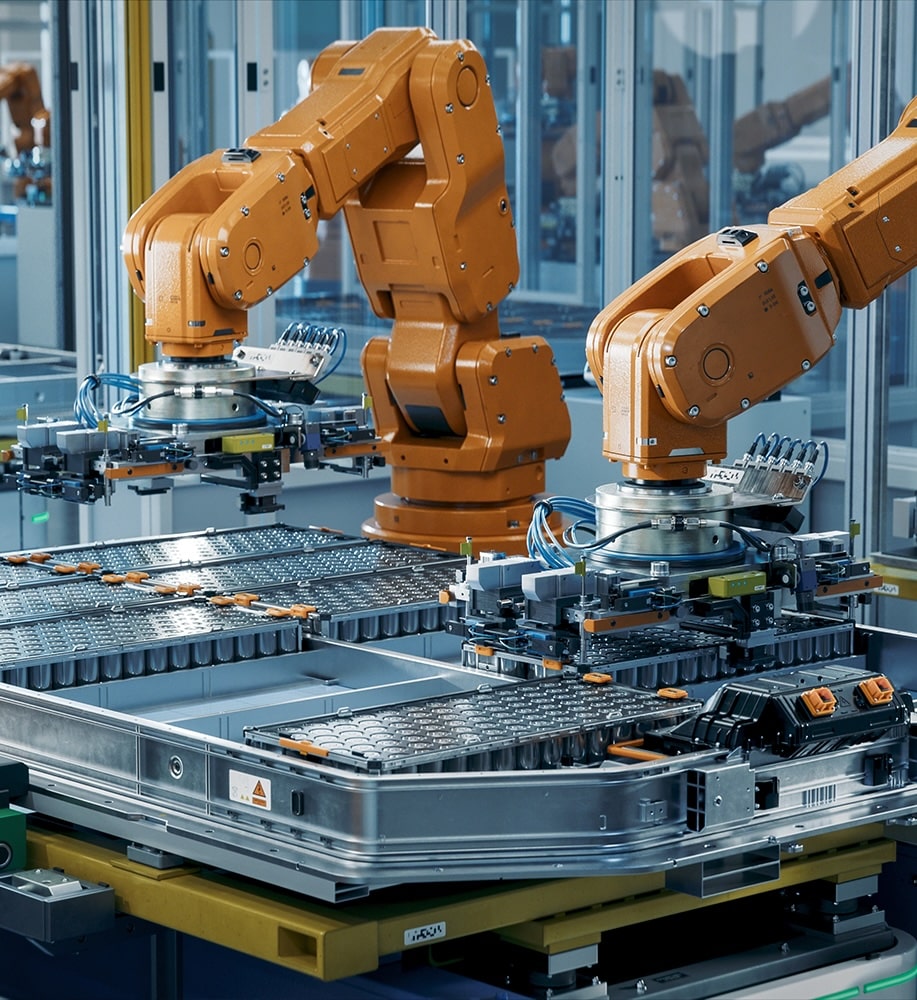

EN SAVOIR PLUSMachines spéciales

AMCC, assure la maitrise d’oeuvre de projets complexes impliquant plusieurs corps de métier.

EN SAVOIR PLUSRigueur & expérience

Industries et secteurs servis

Des secteurs exigeants, une expertise à la hauteur

30 ans d’expérience

5 domaines d’activité

Spatial, médical, horlogerie, énergie, automobile

Ces domaines imposent précision, fiabilité et maîtrise technique totale, des standards que nous intégrons à chaque étape de nos projets, de la conception à la mise en service.

Accompagnement & fiabilité

Pourquoi choisir

le bureau d'études AMCC ?

Avec plus de 30 ans d’expérience, AMCC est un partenaire reconnu pour la qualité de son accompagnement et la fiabilité de ses solutions. Nous vous apportons :

FAQ

Quels types de systèmes ou sous-ensembles mécaniques pouvez-vous concevoir ?

Nous concevons des ensembles mécaniques complets ou partiels : châssis, outillages de production, supports d'équipements, bancs de tests, interfaces mécatroniques, pièces fonctionnelles ou prototypes. Nous travaillons aussi bien sur de la pièce unitaire que sur de la petite série.

Avez-vous l'habitude de concevoir des outillages spécifiques pour intégration ou tests ?

Oui, c'est l'un de nos cœurs de métier. Nous développons des outillages de production, gabarits d'assemblage, outils de bridage, ou bancs de test fonctionnels. Les solutions sont conçues pour être robustes, maintenables, et compatibles avec des cycles en environnement industriel.

Pouvez-vous intégrer des composants haute température ou sous vide dans vos conceptions mécaniques ?

Oui. Nous concevons régulièrement des dispositifs soumis à des environnements sévères (jusqu'à 200–300 °C, atmosphères contrôlées, vide poussé) pour le spatial ou la défense. Nous maîtrisons l'usage de matériaux adaptés comme l'Inconel, le titane, les céramiques techniques ou le graphite usiné.

Est-ce que vous faites du rétro-engineering ou de la modification sur existant ?

Oui. Nous pouvons scanner ou reconstituer un plan 3D à partir d'une pièce existante, mettre à jour une ancienne CAO, ou adapter un outillage déjà utilisé à de nouveaux besoins.

Avez-vous l'expérience d'environnements industriels exigeants ?

Oui. Nous travaillons régulièrement dans les secteurs de l'aéronautique, du spatial, de la défense et de l'énergie. Cela implique le respect de contraintes spécifiques : traçabilité, documentation technique, normes, robustesse mécanique.

Pouvez-vous nous accompagner sur des projets nécessitant des compétences multidisciplinaires ?

Absolument. Notre équipe intègre des compétences en mécanique, électronique et automatisme. Nous pouvons développer des systèmes complets intégrant capteurs, actionneurs et interfaces homme-machine, avec programmation des automates et systèmes de contrôle associés.