Plateaux givrants

Implants intra-oculaires

Implants

intra-oculaires

Lathing

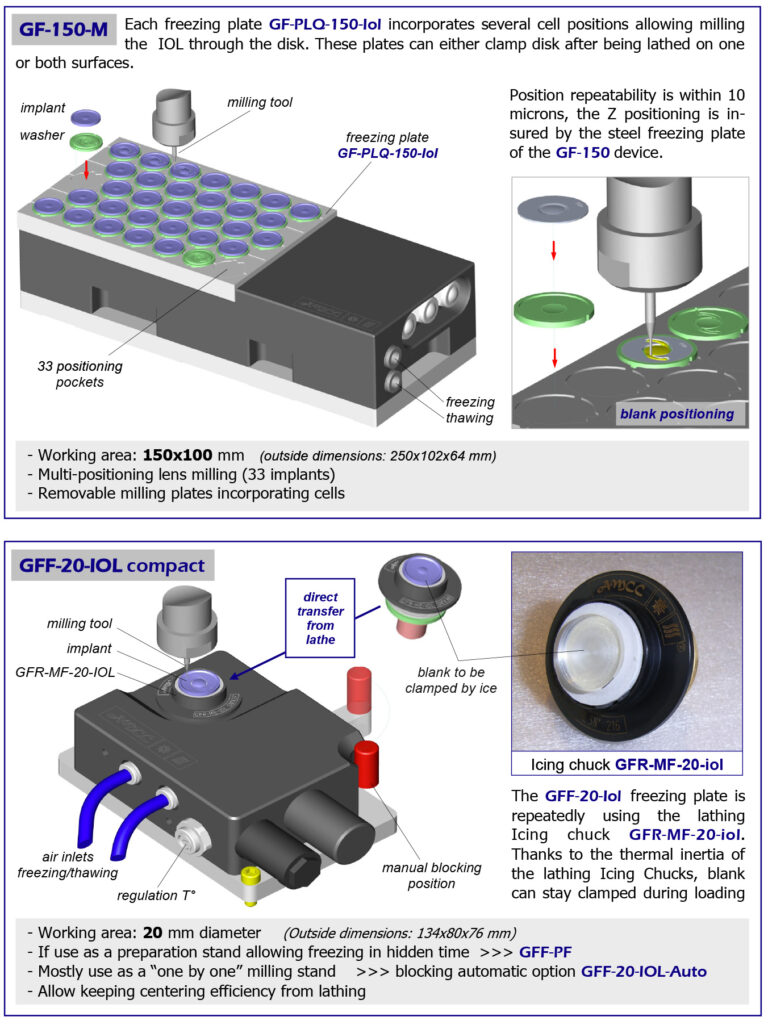

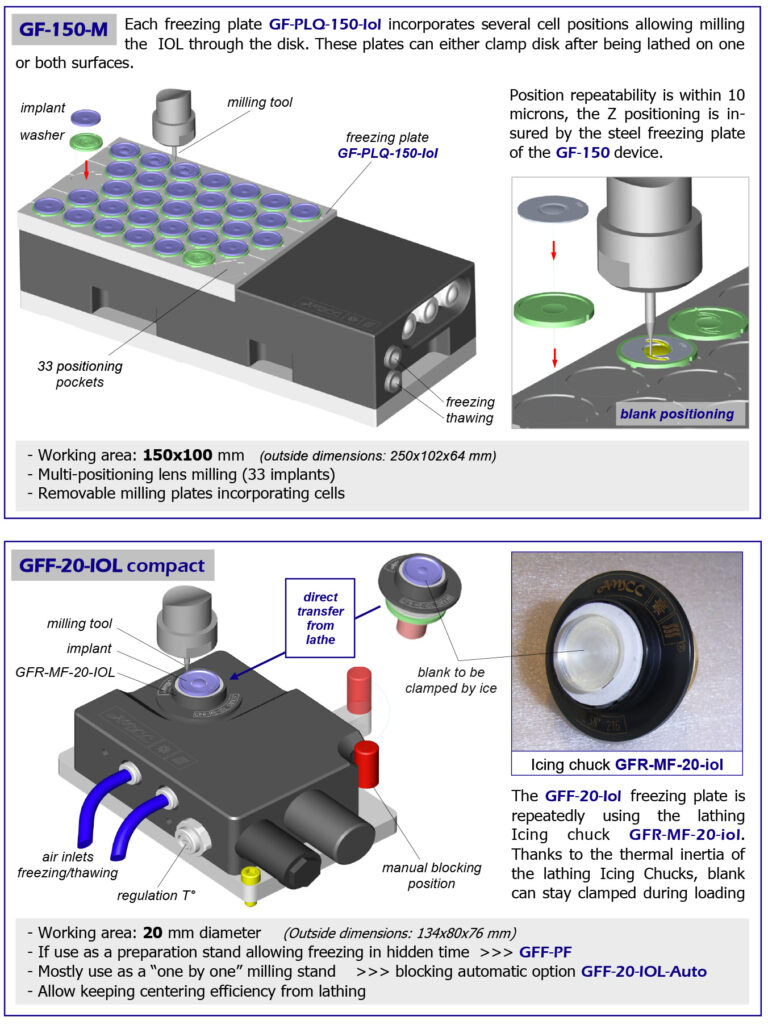

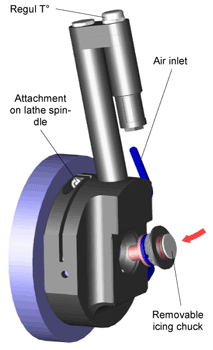

L’utilisation de la plaque de congélation GFR-20-IOL pour le tournage de disques parfaitement arrondis n’est plus une nécessité, car tout recours à une pince est évité. Des disques plus fins peuvent ainsi être utilisés, permettant une économie de matière grâce à un gel profond du noyau et une reposition facile pour l’étape suivante.

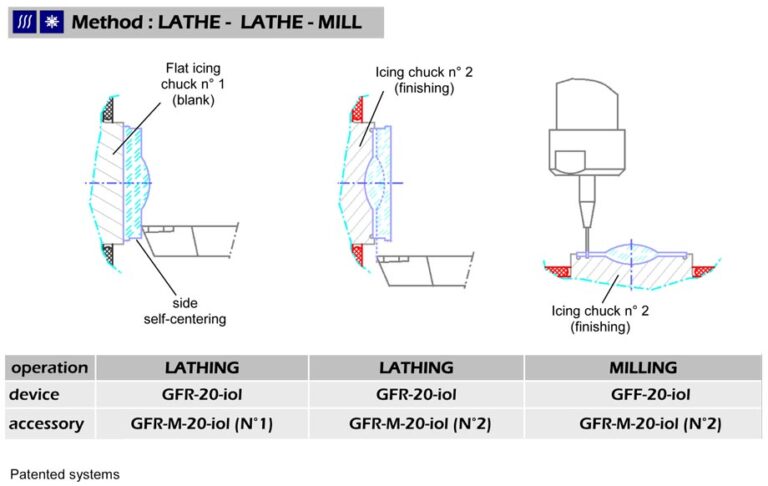

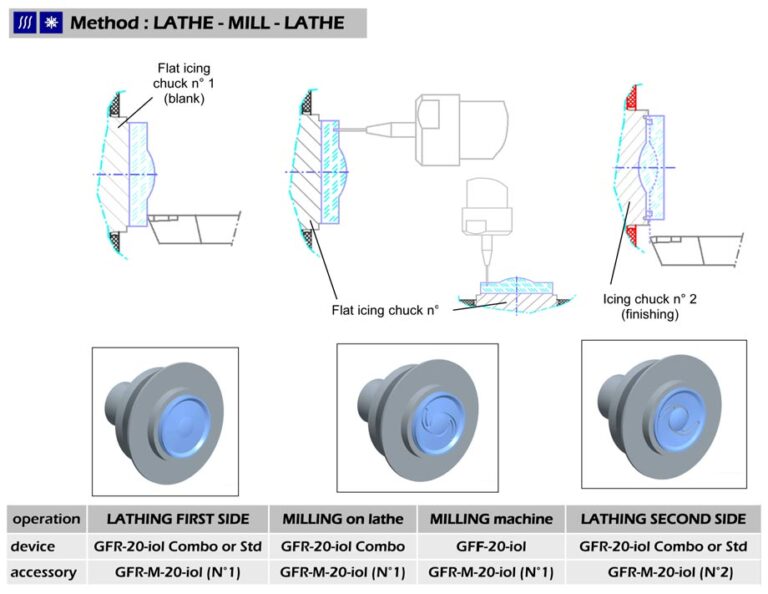

Les mandrins de congélation GFR-20-IOL sont interchangeables afin de s’adapter aux différentes étapes de fabrication. En général, le mandrin utilisé pour la première face est plat pour correspondre à la surface du disque brut, tandis que les mandrins pour la seconde face sont usinés avec une empreinte miroir du profil de la lentille.

Grâce à un dispositif optionnel de centrage externe, le positionnement des disques usinés peut être effectué facilement. Comme la pince d’origine « dead length » est utilisée sous le dispositif de congélation, le passage à une fabrication « classique » reste simple.

(1) Systèmes brevetés

(2) Air comprimé propre et sec (7 bars, 3.2.2. selon la norme AFNOR E 51.301)

Intraocular Lens

« Frost » est un adhésif extrêmement puissant utilisé dans de nombreuses applications micro-mécaniques pour la fixation de pièces minuscules, comme par exemple les aiguilles de montres.

Grâce à cette propriété naturelle, les plaques de congélation AMCC (Icing Plates) l’utilisent comme système de serrage, offrant de nombreux avantages :

-

Liaison rigide obtenue avec différents matériaux tels que le PMMA, les acryliques, le silicone, etc.

-

Serrage mécanique sans contraintes.

-

Le refroidissement profond améliore l’état de surface lors de la coupe, en particulier pour les matériaux hydrophobes.

-

Aucune résidu solide après le déblocage des pièces.

Les plaques AMCC GF sont refroidies par un échangeur thermique(¹) à double flux(¹), ne nécessitant donc que de l’air comprimé(²) pour fonctionner.

Les plaques de congélation sont faciles à utiliser pour la fabrication d’IOL (lentilles intraoculaires) : il suffit de pulvériser de l’eau sur les ébauches, de positionner l’ébauche sur le mandrin réfrigérant ; en quelques secondes, l’eau gèle et l’usinage peut commencer. Le déblocage est encore plus simple en inversant le flux d’air pour passer du refroidissement au dégivrage.

À l’origine développées pour une utilisation dans les ateliers de l’industrie aérospatiale, ces plaques de congélation ont été adoptées dans des secteurs fabriquant des pièces de précision, et plus particulièrement dans l’industrie des lentilles intraoculaires.

Comme indiqué ci-dessus, les plaques de congélation AMCC permettent d’importants gains de productivité tout en améliorant la qualité de fabrication des IOL.

Nous restons à votre disposition pour toute information complémentaire, n’hésitez donc pas à nous contacter.

(¹) Systèmes brevetés

(²) Air comprimé propre et sec (7 bars, 3.2.2. selon AFNOR E 51.301)

Machining Methods

Comme indiqué ci-dessous, les plaques de congélation AMCC permettent d’importants gains de productivité tout en améliorant la qualité de fabrication des lentilles intraoculaires (IOL).

Nous restons à votre disposition pour toute information complémentaire, n’hésitez donc pas à nous contacter.

MFD-2451-IOL

Essai de durabilité par fatigue dynamique selon la norme ISO 11979-3 appendice G

MFC-Vision

Visualisation des déformations pendant l'essai de compression

MFC-1385-IOL

Mesure de la force de compression selon la norme ISO 11979-3 appendice A

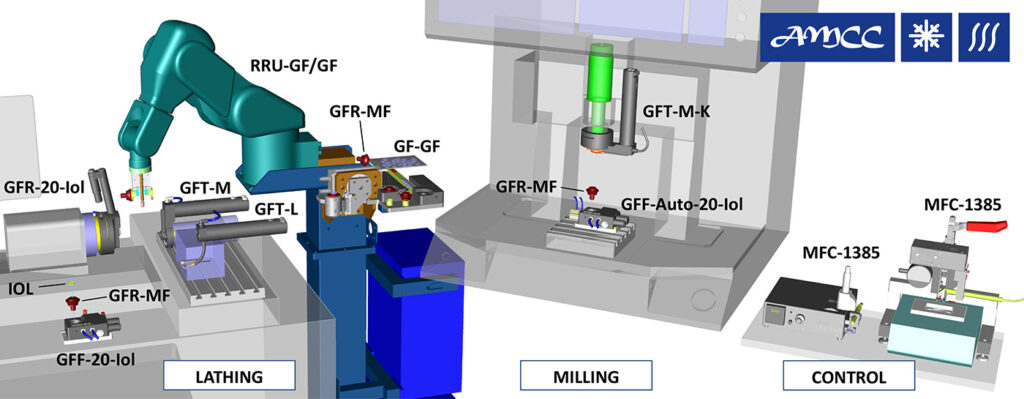

Automatic GF-GF

Semi-automatic GF-GF

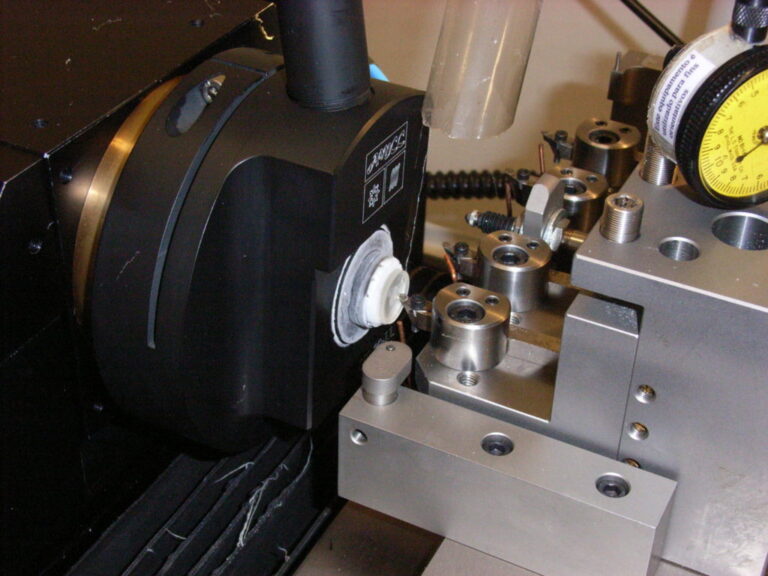

L'unité semi-automatique GF-GF1 est destinée au retournement des IOls, entre l'usinage de la première face et l'usinage de la deuxième face. La fiabilité du système de retournement, associé aux mandrins de glaçage GFR-MF-20-Iols, assure un positionnement extrêmement précis entre les deux faces.

Manual GF-GF

Ils nous font confiance