Design office mechanics

Expertise & know-how

Our expertise and methodology

Tailor-made support

Proven technical expertise

Mechanical design

(2D/3D CAD, calculations, sizing)

Project management

(planning, quality, costs)

We work on projects with high technical added value, in demanding environments.

A clear project methodology

Design & integration

Our engineering engineering

The AMCC design office supports its industrial customers in their turnkey mechanical projects, from design to final integration. Our expertise is based on three complementary areas:

Mechanical design

AMCC supports its customers in the design of mechanical projects and the development of innovative solutions.

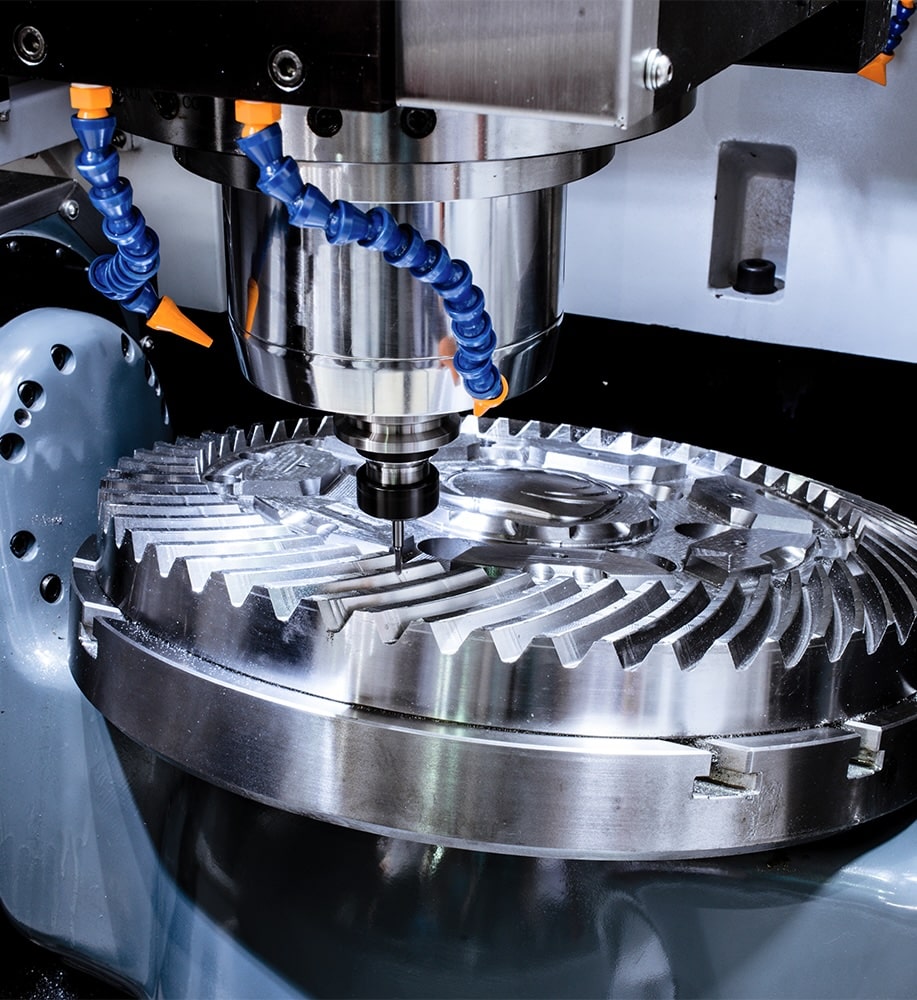

LEARN MOREManufacture

Our experience and our network of partners enable us to support you in your manufacturing projects, from highly precise micro-parts to large-scale assemblies.

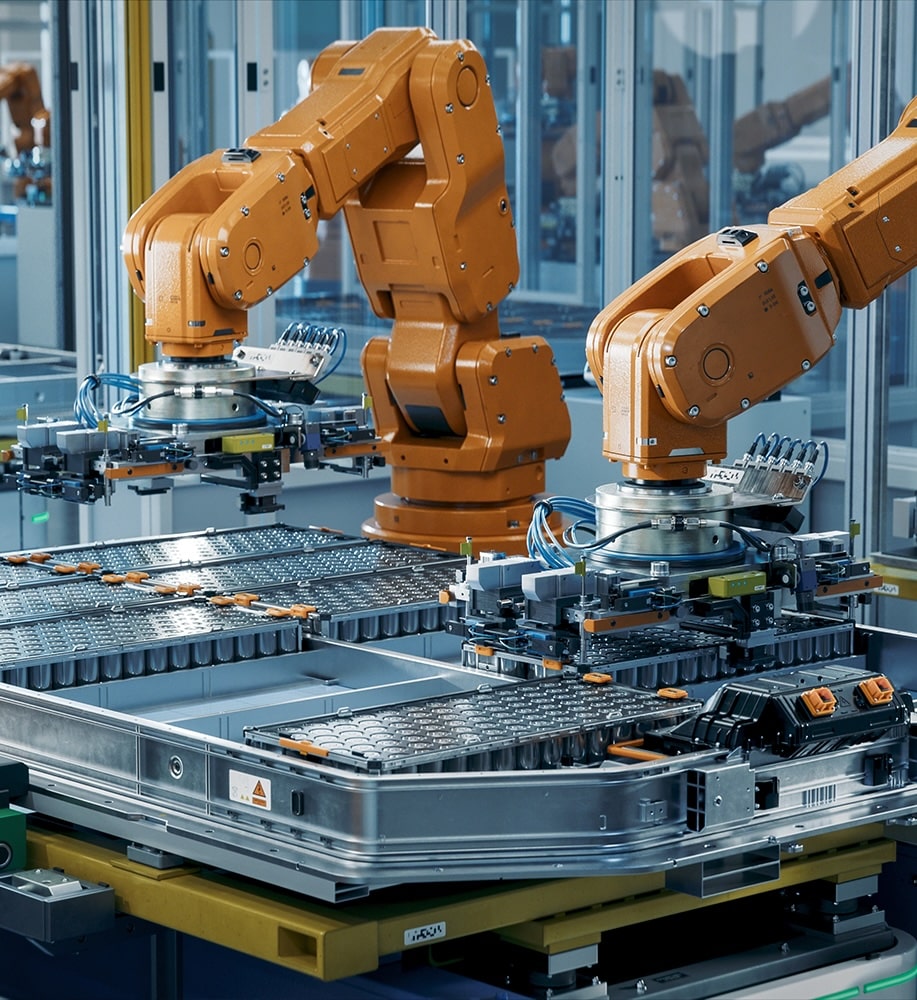

LEARN MORESpecial machines

AMCC provides project management services for complex projects involving several trades.

LEARN MORERigour & experience

Industries and sectors served

Demanding sectors, expertise to match

30 years of experience

5 areas of activity

Space, medical, watchmaking, energy, automotive

These areas demand precision, reliability and total technical control, standards that we incorporate into every stage of our projects, from design to commissioning.

Support & reliability

Why choose

the AMCC design office?

With over 30 years' experience, AMCC is a partner renowned for the quality of its support and the reliability of its solutions. We bring you :

FAQ

What types of mechanical systems or sub-assemblies can you design?

We design complete or partial mechanical assemblies: chassis, production tooling, equipment supports, test benches, mechatronic interfaces, functional parts or prototypes. We work on single parts as well as small series.

Are you used to designing specific tools for integration or testing?

Yes, this is one of our core businesses. We develop production tooling, assembly jigs, clamping tools and functional test benches. The solutions are designed to be robust, maintainable and compatible with cycles in an industrial environment.

Can you integrate high-temperature or vacuum components into your mechanical designs?

Yes, we regularly design devices subjected to severe environments (up to 200-300°C, controlled atmospheres, high vacuum) for the space and defence industries. We have mastered the use of appropriate materials such as Inconel, titanium, technical ceramics and machined graphite.

Do you retroengineer or modify existing systems?

Yes, we can scan or reconstitute a 3D drawing from an existing part, update an old CAD, or adapt tooling already in use to new requirements.

Do you have experience of demanding industrial environments?

Yes, we regularly work in the aerospace, defence and energy sectors. This implies compliance with specific constraints: traceability, technical documentation, standards and mechanical robustness.

Can you work with us on projects requiring multidisciplinary skills?

Absolutely. Our team integrates skills in mechanics, electronics and automation. We can develop complete systems integrating sensors, actuators and man-machine interfaces, with programming of the associated PLCs and control systems.